K

K

K

K

LeanTwin Consulting

We help our clients to optimise, automate and digitize their operations utilizing Lean Six Sigma Methodologies and Digital Twin Techologies.

Our services

Understand & Envision

Understand the AS IS business, map the business functions and capabilities and development of TO BE stage.

Maturity Assessment

Assessing business functions utilizing an I4.0 maturity matrix. Identify Prioritised key Use Cases that maximize business value.

Transformation Roadmap

Conducting an Operational readiness assessment and developing the 3-5 years digital transformation implementation roadmap.

Typical Benefits

Improve Product Quality

Ensure product quality with insight into the performance of operations and processes in real-time to influence and react to customization and minimize the impact on supply chain

Improve Efficiency

Improve productivity – operational efficiency and effectiveness – simulating, analyzing and visualizing manpower, semi – automated and fully automated operations

Envision Opportunities

Leveraging real time data by running the digital twin in parallel with the real machine can help discovering new business opportunities

Asset Reliability

Monitor, simulate and control an asset process or network as an effective strategy to improve system performance.

Optimise Maintenance

Predict issues before breakdowns occur, order Parts and schedule repairs at times that don’t impact production goals.

Improve Safety

Protecting the health and safety of employees and business objectives, by reducing asset- and process-related incidents.

Lean Manufacturing & Digital Twin

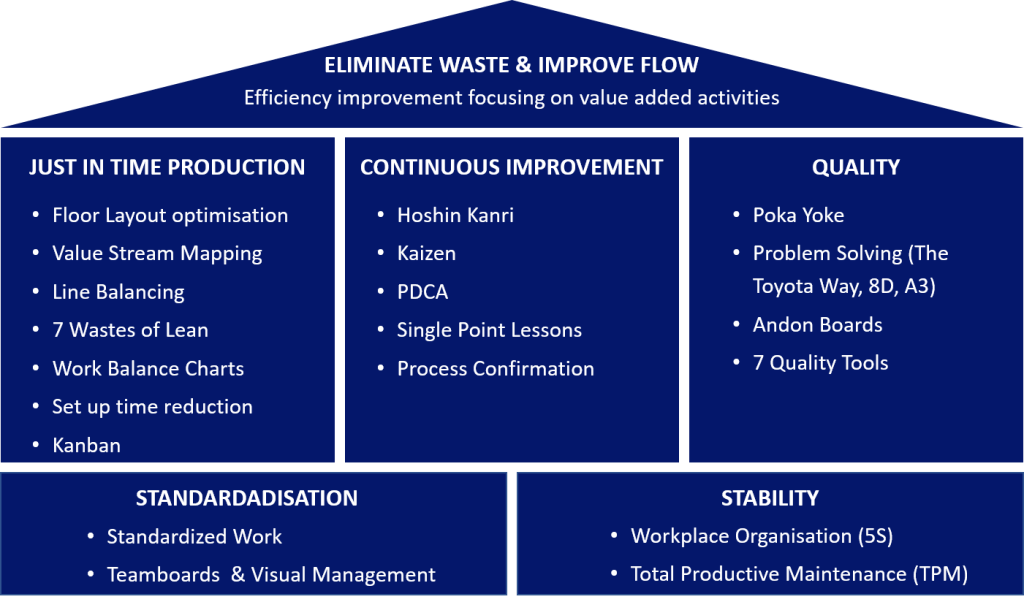

Lean Six Sigma principles have been used in manufacturing to drive efficiency and reduce waste. Digital Twin is able to utilize AI and VR and it is considered a cornerstone of Digital Technologies with numerous applications.

Lean Six Sigma in combination with Digital Twin Technology maximize business value.

House of Lean Tools

Digital Twin Framework

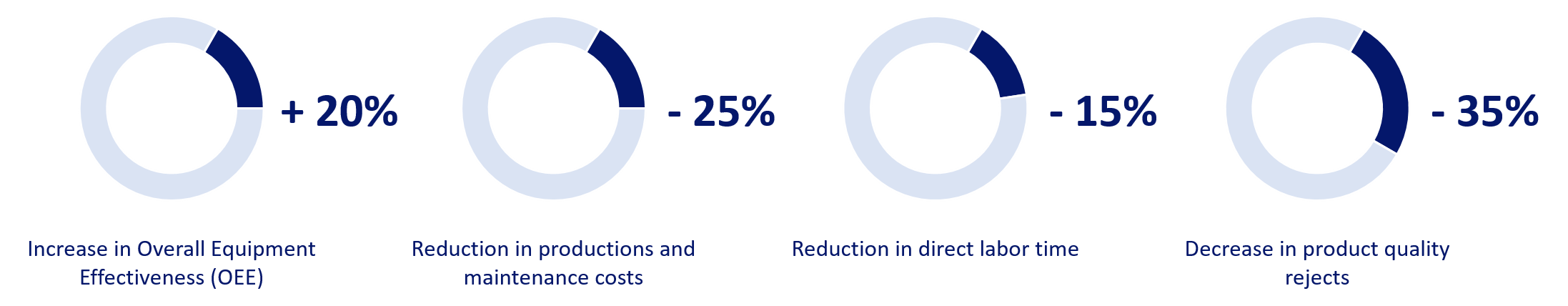

Client Results